AR Standing Seam

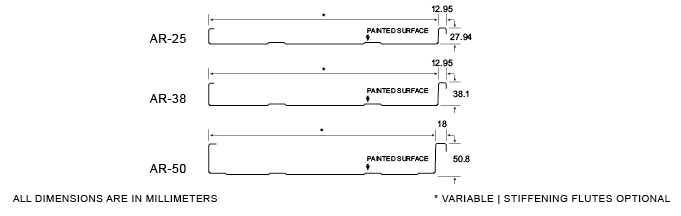

Our Standing Seam AR metal roofing is available in 24 and 22 gauge, in variable widths and with side lap rib heights of 1”, 1 ½” or 2”. Agway’s AR series also features optional, two-piece expansion clips to accommodate movement of the roof, and can be seamed at either 90º or 180º. With a 180º seam and optional seam caulking, panels can be used on low slopes (AR-38 down to 1.5/12 and AR-50 down to 0.5/12).

Unlike many traditional alternatives like slate or tile, our Standing Seam Profile is easy to install, more cost effective, 100% recyclable and facilitates more creativity in design. In fact, this profile can even be curved!

Whether you choose a profile from our Standing Seam, Nail Strip, or Snap Lock roof cladding systems, the result will be a stunning, architecturally distinctive roof that installs easily and has no exposed fasteners. All these durable Agway roof cladding products are available in a full range of stock colours, in variable panel widths, and with optional stiffening flutes. All are single skin applications and must be applied over a solid substrate and waterproof membrane, using clips at a maximum of 2’ centres. A full range of flashings and accessories are available from Agway to complete your project.

Measurement Type

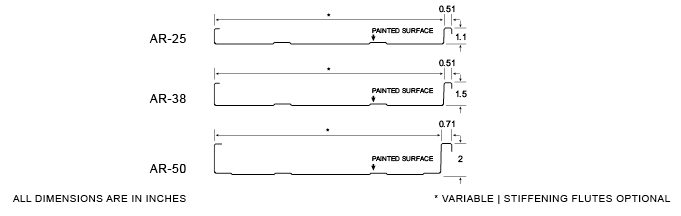

Profile Picture

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| AR-25 | 3/12 – 12/12 | 0.0236” – 0.030” | 2′ 6″ – 45′ | 6″ – 28″ |

| AR-38 | 1.5/12 – 12/12 | 0.0236” – 0.030” | 2′ 6″ – 45′ | 6″ – 28″ |

| AR-50 | 0.5/12 – 12/12 | 0.0236” – 0.030” | 2′ 6″ – 45′ | 8″ – 24.5″ |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For AR-25, AR-38 or AR-50 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 48”

Standard Panel Widths

| GAUGE | AR-25 | AR-38 | AR-50 |

|---|---|---|---|

| 24 | 21.06″ | 20.06″ | 18.52″ |

| 22 | 21.06″ | 20.06″ | 18.52″ |

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

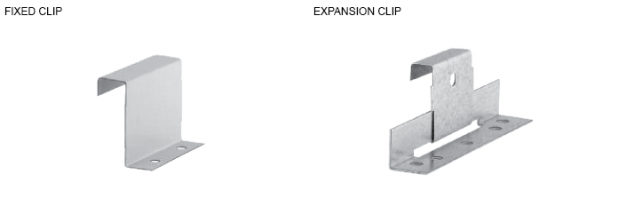

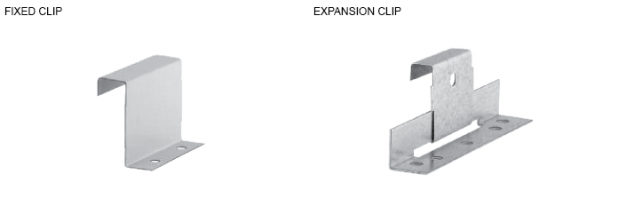

- Concealed hold-down clips

- Knee Caps available

- Optional two-piece expansion clip to accommodate roof movement

- 24 gauge can be seamed 90° and 180°; 22 gauge can be seamed 90° only

- Butyl Tape is recommended in 90° seams

- Able to be curved – minimum sheet length 5’-0”

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that AR Series profiles be applied over waterproof membrane

- Clips at maximum 2’ centres – 2 fasteners per clip

- Mechanical and Hand Seamer required. For seamer purchase & rental visit the D.I. Roof Seamers website – or by calling D.I. Roof Installers at 1-888-343-0456

Hold-Down Clip Detail

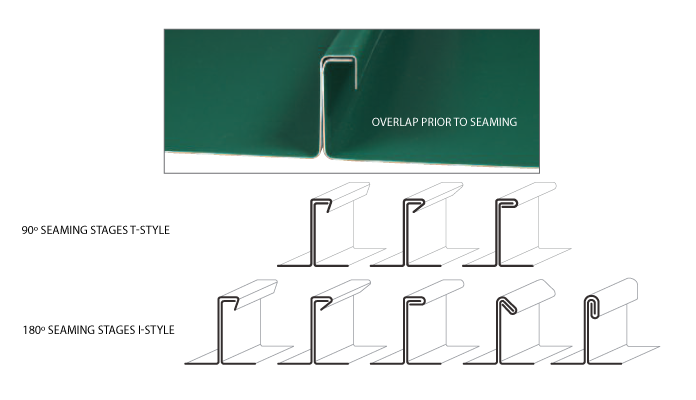

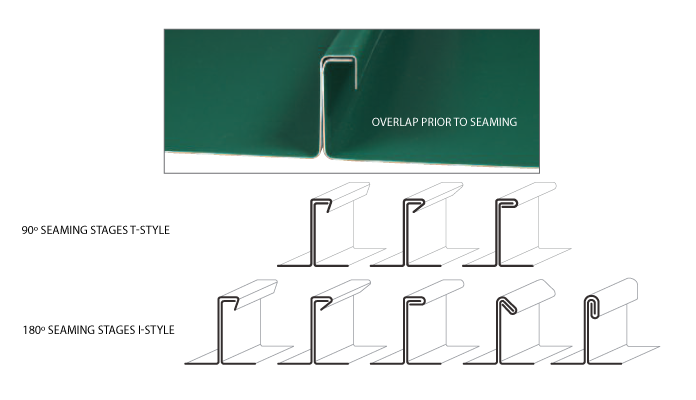

Overlap Seaming Options

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| AR-25 | 3/12 – 12/12 | 0.610 – 0.762 mm | 0.76 – 13.71 m | 152 – 711 mm |

| AR-38 | 1.5/12 – 12/12 | 0.610 – 0.762 mm | 0.76 – 13.71 m | 152 – 711 mm |

| AR-50 | 0.5/12 – 12/12 | 0.610 – 0.762 mm | 0.76 – 13.71 m | 203 – 622 mm |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For AR-25, AR-38 or AR-50 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 1,219 mm

Standard Panel Widths

| GAUGE | AR-25 | AR-38 | AR-50 |

|---|---|---|---|

| 24 | 21.06″ (535 mm) |

20.06″ (509.5 mm) |

18.52″ (470 mm) |

| 22 | 21.06″ (535 mm) |

20.06″ (509.5 mm) |

18.52″ (470 mm) |

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Concealed hold-down clips

- Knee Caps available

- Optional two-piece expansion clip to accommodate roof movement

- 24 gauge can be seamed 90° and 180°; 22 gauge can be seamed 90° only

- Butyl Tape is recommended in 90° seams

- Able to be curved – minimum sheet length: 1.52m

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that AR Series profiles be applied over waterproof membrane

- Clips at maximum 61 cm centers – 2 fasteners per clip

- Mechanical and Hand Seamer required. For seamer purchase & rental visit the D.I. Roof Seamers website – or by calling D.I. Roof Installers at 1-888-343-0456

Hold-Down Clip Detail

Overlap Seaming Options