Tuff Board

Features

- High Density Polypropylene Sheet laminated to 3/8″ or 1/2″ plywood

- Government-Accepted for Food Production areas (#3100-3E/144 & #3100-3L/126)

- Strong

- Durable top quality plastic and laminate

- Excellent light reflection

- Will not rust or mildew

- Easy to clean – pressure wash

- Bright smooth ultra-white finish

- Easy to install

- Complete line of accessories available

Resources

Applications

Interior Linings where exposed to dampness and pressure washing, Refrigerated Coolers, Retail or Dairy Operations

Storage Sizes

48” x 8’. Thicknesses:

0.030″ and 0.060″ on 3/8″ plywood

0.060″ on 1/2″ plywood

48″ x 10′ Thickness:

0.040″ on 1/2″ plywood

Storage

Acclimate panels for 24 hrs. prior to installation. This product will expand or contract under certain circumstances.

Installation

Pre-drill holes 1/8” larger than screws. Maximum support spacing is 16” o/c. Maximum fastener spacing along the edge of the sheet is 8” (allowing a minimum of 1” from edge of sheet). Maximum fastener spacing along the intermediate studs is 12”. When fastening to a solid wall, an approved adhesive will help to ensure flatness. For Tuff Board, adhesive must be approved for wood-to-wood contact.

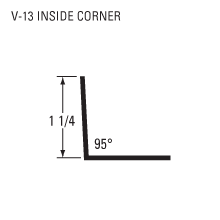

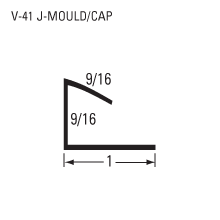

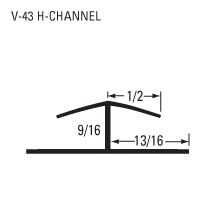

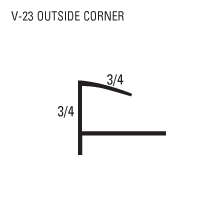

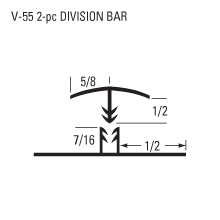

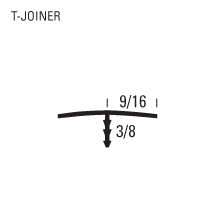

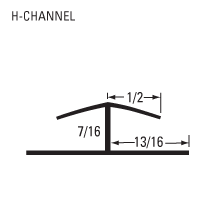

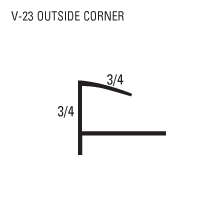

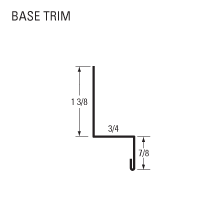

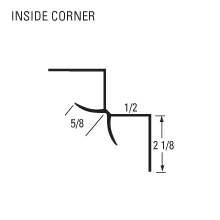

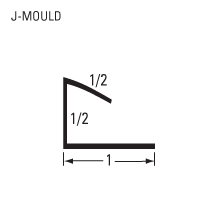

Accessories

- 3/4” Two-piece Drive Rivet, Nylon

- 1-1/2” Two-piece Drive Rivet, Nylon

- #8 x 1-1/2” White Stainless Type A Robertson – Panhead Screws

- Siliconized Interior Acrylic Latex Sealant

3/8” Sheets – 8’ or 12’

1/2” Sheets – 8’