Trius Residential Wall Cladding

Trius, Agway Metals’ latest breakthrough wall cladding profile combines unmatched durability with aesthetic finesse, elevating your project to new heights. Effortlessly tailor your design with customizable lengths, reaching up to 240 inches (6096 mm). Trius features a hidden fastener system, enhancing its sleek appearance and streamlining installation. This not only elevates its visual appeal but also reduces labour costs and installation time.

Available August 2024

Trius Residential Wall Cladding

Features:

- Manufactured from 24 and 26 ga. Prepainted Steel

- Minimum length 36” (914.4 mm), custom lengths 240” (6096 mm) max length

- Hidden fastener installation – secure to supports with fasteners in the center of the slots at spacings specified by project engineer (do not over-tighten)

- Ease of installation saves on labour

- 18” (457.2 mm) Coverage

- Uses conventional trims

Applications:

- Accent Panel

- Vertical Wall Installation (with special trims)

- Horizontal Wall Installation (Installs bottom to top)

Note(s):

- Oil canning may be present due to various factors

- Oil canning is not a valid reason for rejection of this product

Measurement Type

Profile Picture

Trius

Trius, Agway Metals’ latest breakthrough wall cladding profile combines unmatched durability with aesthetic finesse, elevating your project to new heights. Effortlessly tailor your design with customizable lengths, reaching up to 240 inches (6096 mm). Trius features a hidden fastener system, enhancing its sleek appearance and streamlining installation. This not only elevates its visual appeal but also reduces labour costs and installation time.

Available August 2024

Trius Light Gauge Wall Cladding

Features:

- Manufactured from 24 and 26 ga. Prepainted Steel

- Minimum length 36” (914.4 mm), custom lengths 240” (6096 mm) max length

- Hidden fastener installation – secure to supports with fasteners in the center of the slots at spacings specified by project engineer (do not over-tighten)

- Ease of installation saves on labour

- 18” (457.2 mm) Coverage

- Uses conventional trims

Applications:

- Accent Panel

- Vertical Wall Installation (with special trims)

- Horizontal Wall Installation (Installs bottom to top)

Note(s):

- Oil canning may be present due to various factors

- Oil canning is not a valid reason for rejection of this product

Measurement Type

Profile Picture

Trius

Trius, Agway Metals’ latest breakthrough wall cladding profile combines unmatched durability with aesthetic finesse, elevating your project to new heights. Effortlessly tailor your design with customizable lengths, reaching up to 240 inches (6096 mm). Trius features a hidden fastener system, enhancing its sleek appearance and streamlining installation. This not only elevates its visual appeal but also reduces labour costs and installation time.

Available August 2024

Trius Commercial Wall Cladding

Features:

- Manufactured from 24 and 26 ga. Prepainted Steel

- Minimum length 36” (914.4 mm), custom lengths 240” (6096 mm) max length

- Hidden fastener installation – secure to supports with fasteners in the center of the slots at spacings specified by project engineer (do not over-tighten)

- Ease of installation saves on labour

- 18” (457.2 mm) Coverage

- Uses conventional trims

Applications:

- Accent Panel

- Vertical Wall Installation (with special trims)

- Horizontal Wall Installation (Installs bottom to top)

Note(s):

- Oil canning may be present due to various factors

- Oil canning is not a valid reason for rejection of this product

Measurement Type

Profile Picture

Product Sheet

![]()

Platinum HT-B Underlayment

PLATINUM HT-B is a high temperature self-adhered waterproofing membrane made with an advanced Black Butyl rubber adhesive formulation and is designed for use as secondary ice and water protection in steep slope roofing applications. It offers premium protection against water infiltration from snow, ice dams, and wind driven rain. It can be used under most primary roofing materials such as residential or commercial metal, mechanically attached concrete or clay tiles, primed cedar shakes, and asphalt or composite shingles.

Platinum HT-B combines a GRIPSPOT™ patented slip resistant walking surface with a high strength, high temperature black butyl adhesive backing that allows for both low temperature (32°F / 0°C) and rising deck adhesion and high temperature flow stability up to 265°F(129.4°C).

The GRIPSPOT™ walking surface features raised fibrous traction spots and smooth channels for shedding water. This provides faster dry times while offering unmatched slip resistance in all types of weather and surface conditions; dry, wet, frozen, and dusty. Platinum HT-B comes with a silicone treated split-release liner for ease of removal during installation.

- GRIPSPOT™ (Patent # 2,938,005) slip resistant walking surface

- Unique Black Butyl adhesive provides premium bond to plywood or OSB roof decks

- Longer shelf life 18 months +

- No VOC’s and chemically compatible with EPDM and TPO products

- Nail sealable – meets and exceeds ASTM D1970

- Low installation temperature (32°F / 0°C) and rising

- Watertight laps without special treatment or primers

- 180 day UV exposure

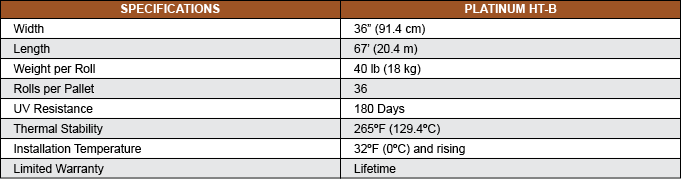

Specifications

Technical Data

Installation Instruction

USE:

Platinum HTB is a high temperature, self-adhered waterproofing membrane made with an advanced black butyl rubber adhesive formulation and designed for use in steep slope roofing applications 2:12 and greater. It offers premium protection against water infiltration from snow, ice dams, and wind driven rain. Platinum HTB is designed for use under most primary roofing materials such as residential or commercial metal, mechanically attached concrete or clay tiles, primed cedar shakes, and asphalt or composite shingles.

STORAGE:

For best results store Platinum HTB upright in its original packaging in a well-ventilated area at room temperature between 40°F (4.4°C) and 90°F (32°C). If product has been stored at a high temperature above 90°F (32°C) it may become difficult to remove the release liner backing. To correct this, move product to a cooler location. Once cooled, the release liner can be easily removed.

DECK PREPARATION:

Platinum HTB should be installed over a clean, smooth, and dry deck. The deck should also not have any voids, protrusions, damaged or unsupported areas. For re-roofing projects, replace any water damaged sheathing and sweep roof deck thoroughly removing dust, dirt and loose nails. Do not install over old roof covering.

APPLICATION:

For best results Platinum HTB should be installed when the air, membrane, and substrate temperature is over 40°F (4.4°C). However, Platinum HTB can be installed in temperatures as low as 32°F (0°C) and rising. Priming is not required when attaching to wood or OSB decks. Concrete or masonry decks should be primed with a solvent or water based primer that meets ASTM D41 for self-adhesive membranes. Membrane to be applied in shingle lap fashion working from the low point to the high point of the roof. Apply the membrane in valleys before the membrane is applied to the eaves. Platinum HTB is to be laid out horizontally (parallel) to the eave with the printed side up. Horizontal overlaps to be 3” using the flat designated selvage edge. For best adhesion performance it is recommended to not overlap up onto the Gripspot walking surface. For end laps it is recommended to overlap a minimum of 6” and nail 1” in from the edge along the vertical end lap with 6” spacing between nails. To increase adhesion a water based primer can be used along end lap. End laps should be offset a minimum of 6 feet on adjacent courses. Where it is necessary to overlap Platinum HTB onto the Gripspot walking surface such as over the ridge it is recommended to cap nail along the outer edge 1” in at 6” intervals. Note if underlayment will be left exposed for an extended period in high wind areas it is also recommended to nail along the outer edges of the roof along the rake or eave.

For easier installation, it is recommended to cut the membrane into manageable lengths. Then peel back one side of the split release liner and apply in position on the roof deck and then press in place by hand or with a weighted roller to increase adhesion to the deck. Once one side has been pressed to the deck peel back the remaining half of the release liner and press down to adhere to the roof deck again using a weighted roller to increase adhesion. For improved adhesion hand rolling over the selvage edge and directly above the selvage edge using a weighted roller is recommended. If a roller is not available or not considered safe, walk on all laps, and as much of the field area as possible.

For Cold Weather Applications 32°F (0°C) or below, a primer should be used and the upper most selvage edge blind nailed using 3/8” head roofing nails 1” or longer. Space nails along edge at 12” intervals using the marked locations. For best results, allow Platinum HTB to ambiently warm to room temperature prior to application.

For Steep Slope Applications (5:12 or greater), high wind areas, or when installing at temperatures greater than 100°F (38°C), it is recommended to blind nail the selvage edge area as per above under cold weather application.

Platinum HTB should be applied under the metal drip edge along the rakes and over the metal drip edge along the eaves unless otherwise specified by local building codes. Do not fold Platinum HTB over the roof edge unless the edge is to be subsequently covered over by a drip edge or other flashing material.

In areas where ice damming can occur, install Platinum HTB from the eaves up the roof to a point not less than 24 inches inside the exterior wall, measured horizontally. Consult your local building code for specific requirements.

For valley applications, peel the release liner; center the sheet over the valley and hand press in place from the center of the valley outward. Note: It is very important Platinum HTB stay in contact with the roof deck into and out of the valley area. Platinum HTB should never be suspended or bridge a valley. It is recommended to follow up with a weighted roller or by walking on the surface. Give special attention to ALL perimeter edge areas and overlaps.

Repair holes, fish mouths, tears, and any other penetration damage to the membrane with a round patch of membrane extending passed the damaged area by 6 inches in all directions. Do not install fasteners through membrane over any unsupported areas of the structural deck, such as over joints between adjacent structural panels.

PRECAUTIONS:

Platinum HTB is a moisture and vapor barrier and therefore must be installed above a properly ventilated space(s). Follow ALL building codes applicable to your geographical region and structure type. Platinum HTB is not designed for indefinite outdoor exposure. Final roofing should be installed within 180 days of underlayment installation.

These provided Installation instructions are designed to offer recommendations to achieve best performance from our products. However, it is imperative that you follow ALL building codes or architectural specifications applicable to your geographical region and structure type.

CAUTION – Read Good Safety Practice Below

As with any roofing product, always follow safe roofing codes & practices (OSHA) and always use and wear fall protection devices when working on roofs. Release liners are slippery and should be removed from work area immediately after application. Use caution when walking or standing on Platinum HTB as slip resistance may vary with surface conditions, weather, footwear and roof pitch. Failure to use proper safety gear and footwear can result in serious injury.

Measurement Type

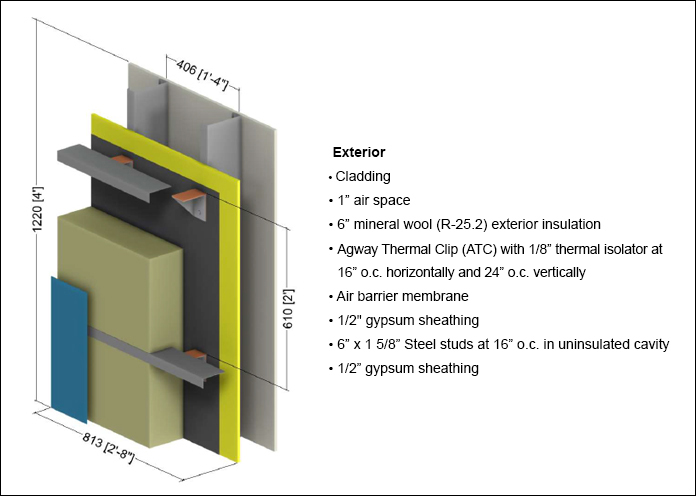

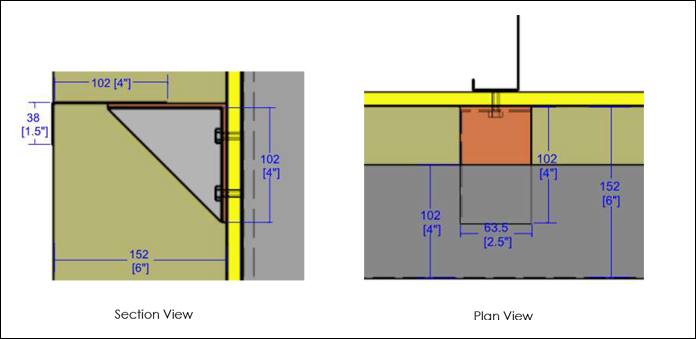

Agway Thermal Clip (ATC)

Agway Thermal Clip (ATC) provides support for cladding panels while acting as a thermal break in exterior insulated walls. The clips are made from 16 gauge galvanized steel lined with cork tape, a material known for its insulating properties. The Thermal Clips are paired with Sub Girt L Bars, which are positioned to fit the thickness of the insulation panels and can support vertical and horizontal cladding in a variety of wall compositions. Thermal bridging is prevented by the cork tape facilitating energy saving goals.

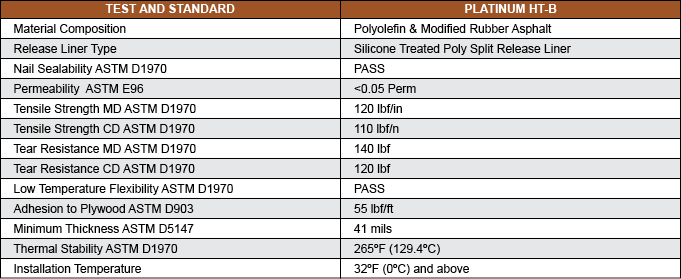

Span Tables for 4” Agway Thermal Clip (ATC)

The spacing shown above are based on the following,

- Analysis of the bracket, girts and mechanical attachments are in general accordance with the National Building Code of Canada (NBCC) using Limit State Design (LSD).

- Thermal Clip: 4” by 4” by 2.5” 16ga. thermally broken clip (ASTM A653 CS Type B, G-90 ( Z275 ), min yield stress = 33ksi).

- Girt Type: 4” x 1-1/2” 16ga. G-90 ( Z275 ) (min yield stress = 33ksi).

- Girt to Thermal Clip Fasteners: (2) # 14 x 1″ Self Drilling Galvanized Screws per bracket.

- Concrete Substrate Anchor: (2) ¼” Tapcon screw anchors (min. embedment = 1-1/2”, f’c = 2000 psi).

- 5 psf [0.24 kN/m2] dead load with exterior face of panel at 5-3/4” when measured from concrete substrate.

- Components were analyzed based on 1.25D + 1.4W load combination using the nominal loads listed above.

- Vertical and horizontal girt deflections limited to 0.125” and L/60 respectively.

- Table 1: Thermal Transmittance of the Evaluated Wall Assembly

The table above is intended to provide an estimated allowable spacing for the brackets and is not to be used for construction. Analysis of the bracket, girt and mechanical attachments was conducted by MORRISON HERSHFIELD. Results have not been verified by finite element analysis or testing. Calculations stamped by a licensed engineer should be provided on a project by project basis to ensure all components meet the local code requirements.

Example Vertical Wall Assembly

Thermal Clip Horizontal Girt Arrangement

Measurement Type

Polyurethane / Polyester

Resources

Available Colours

Polyurethane

Polyester

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation

Measurement Type

Print Series

RepliKote enables architects and designers to create stunningly realistic faux exteriors and interior product application surfaces, while offering significant advantages over other alternatives.

Creative Freedom, Unlimited Applications

If you can imagine it, you can express it – RepliKote enables designers to easily and convincingly emulate precious metal finishes, exotic woods, natural stone, or virtually any creative imagery. RepliKote’s unique manufacturing technology yields gorgeous pre-finished metals that are totally compatible with conventional fabrication techniques.

For architects and builders, the advantages of RepliKote opens a new world of affordable creativity.

Resources

Available Colours

Print Series

Fabrication and Installation Advantages

- Offers unique and convincing emulations of real or imagined images, along with considerable economic, environmental and operational advantages

- Ensures the desired visual aesthetics are controllable, consistent and permanent, throughout the entire coil

- Reduces the cost of materials, installation and maintenance

- Is compliant with traditional metal fabrication and installation methods

- Dramatic weight savings reduces cost of transport and installation in addition to up-front material cost savings

More Efficient – More Cost Effective!

- Cost effective alternative to exotic metals

- Is easy to clean and virtually maintenance-free

Coil Availability

- 24 Gauge

- 22 Gauge

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation

Measurement Type

Wrinkle Coat

Wrinkle Coat is a highly durable, textured paint system that brings differentiation and originality to residential, commercial and architectural buildings. Typical applications include roof panels, wall panels and other building accessories.

The textured coating gives building products a consistent attractive appearance. It offers superior weatherability with a high resistance to chalking, fading and scratching.

Resources

Available Colours

Wrinkle Coat

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation

Measurement Type

Barrier Series

Barrier Series comprises a factory applied primer and polyvinyl chloride (PVC) topcoat. The PVC coating can be applied to both sides of the sheet in thicknesses of 100mm, 200mm or 300mm. Typically Barrier Series coated steel is used in more aggressive industrial applications where the environments are harsher than typical industrial locations.

Resources

Available Colours

Barrier Series

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation

Measurement Type

Metallic / Elite Series

The Metallic Series is a 1-pass, 2-coat process that provides a unique and brighter colour for use in more prestigious applications. This system provides excellent weathering and protective properties.

Resources

Available Colours

Metallic Series

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation

Measurement Type

10000 Series

The 10000 Series is a 2-coat system based on the Kynar 500 resin system. 10000 Series colours are used primarily on more prestigious applications and thus they are typically used less frequently than Perspectra Series colours. This system has superior colour retention and formability properties but, because it requires 2 passes through the paint line, 10000 Series colours are more expensive than the Perspectra Series.

Resources

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation

Measurement Type

Perspectra Plus Series™

Perspectra Plus Series™ is the next generation in our Perspectra Series® paint system. Perspectra Plus Series™ is now even more resistant to chalk, fade, chemical degradation and scratching. It uses state of the art Silicone Modified Polyester (SMP) technology and a new resin backbone which provides enhanced performance to end-users. The proven benefits include superior colour fade resistance to weathering, improved gloss retention and maximum hardness against scratching. The Quality and Performance specification offers 40 years of film integrity and 30 years of stringent colour fade and chalk values for building industry applications like roofing and cladding across Canada and the continental US. Perspectra Plus Series™ is available on hot dip galvanized and on highly corrosion resistant Galvalume™ (55% Aluminum – 45% Zinc alloy coating).

Resources

Available Colours

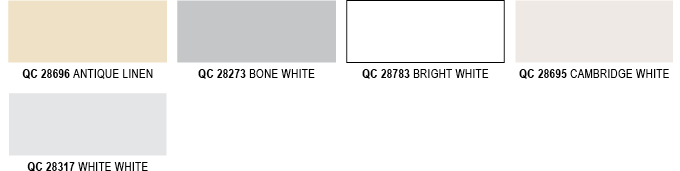

Whites

Standard Colours

Earth Tones

Exotics

Colour Matching

Colour can vary slightly between paint batches and production runs. As well, different paint systems will weather differently over extended periods of time. To improve colour matching and minimize the risk of varying colours on a building, we recommend:

- Order enough material of each colour from one supplier to complete the project

- Cross reference previous orders if additional material is required for a project

- If replacing damaged sheets, try to use other existing sheets in the repair area and install new sheets all in one elevation