Snap Lock

Designed for its ease of installation, Agway’s Snap Lock panel system offers variable width panels that install easily – just attach the hold down clip along the panel rib and snap each panel into the previous one. Featuring hidden clips with no exposed fasteners, like Nail Strip, Agway’s Snap Lock Profile is easy to install and, making it a popular choice for a wide range of residential, agricultural or commercial projects.

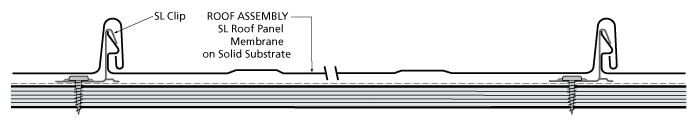

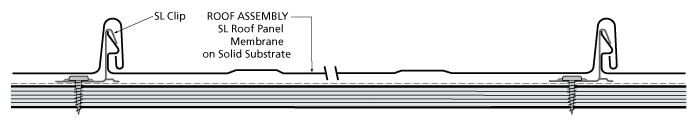

Whether you choose a profile from our Snap Lock, Standing Seam, or Nail Strip roof cladding systems, the result will be a stunning, architecturally distinctive roof that installs easily and has no exposed fasteners. All these durable Agway roof cladding products are available in a full range of stock colours, in variable panel widths, and with optional stiffening flutes. All require a single skin application and must be applied over a solid substrate and waterproof membrane, using clips at a maximum of 2’ centres. Knee Caps are also available (same changes).

Resources

Measurement Type

Profile Picture

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Hidden clips for easy installation

- Knee Caps available

- No seamer required

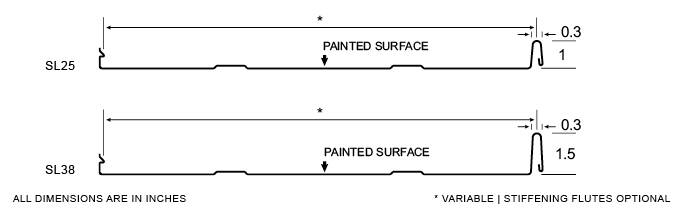

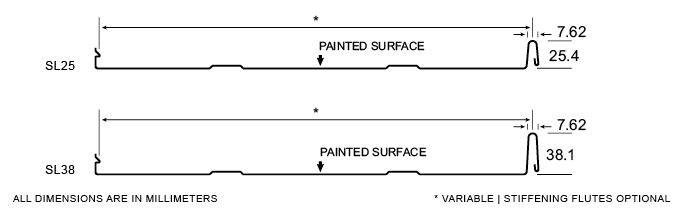

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| SL25 | 3/12 – 12/12 | 0.0236″ | 2′ 6″ – 45′ | 10″ – 28″ |

| SL38 | 1.5/12 – 12/12 | 0.0236 | 2′ 6″ – 45′ | 10″ – 28″ |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Clips at maximum 2’ centers – 2 fasteners per clip

- Snap-in place design

Standard Panel Widths

| GAUGE | SL25 | SL38 |

|---|---|---|

| 24 | 20.81″ | 19.31″ |

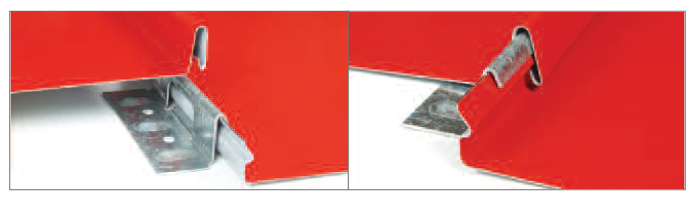

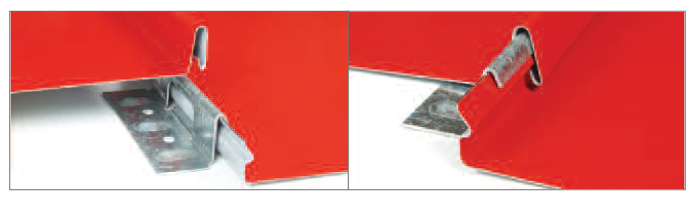

Hold-Down Clip Detail

Sheet Overlap Detail w/Hold-down

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Hidden clips for easy installation

- Knee Caps available

- No seamer required

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| SL25 | 3/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

| SL38 | 1.5/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Clips at maximum 0.61 m centers – 2 fasteners per clip

- Snap-in place design

Standard Panel Widths

| GAUGE | SL25 | SL38 |

|---|---|---|

| 24 | 529 mm | 490 mm |

Hold-Down Clip Detail

Sheet Overlap Detail w/Hold-down