Nail Strip

Agway’s Nail Strip panel system offers variable panel widths, two rib heights and easy installation, making it the ideal choice for seasoned contractors or do-it-yourselfers. Using a continuous nail strip that requires no seamer, Agway’s Nail Strip systems facilitate easy installation, making them a popular choice for residential, agricultural or commercial projects.

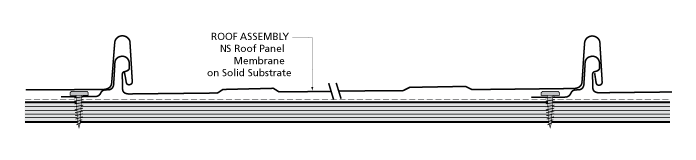

Whether you choose a profile from our Nail Strip, Standing Seam, or Snap Lock roof cladding systems, the result will be a stunning, architecturally distinctive roof that installs easily and has no exposed fasteners. All these durable Agway roof cladding products are available in a full range of stock colours, in variable panel widths, and with optional stiffening flutes. All require a single skin application and must be applied over a solid substrate and waterproof membrane. Knee Caps are also available (same changes as above).

Measurement Type

Profile Picture

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Continuous nail strip

- Knee Caps available

- No seamer required

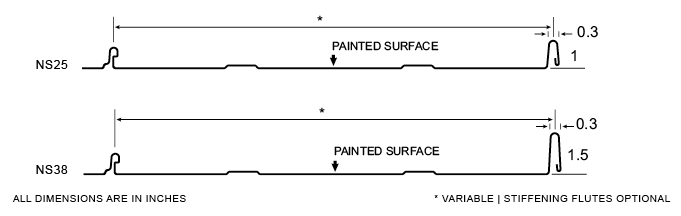

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| NS 25 | 3/12 – 12/12 | 0.0236” | 2′ 6″ – 45′ | 10″ – 28″ |

| NS38 | 1.5/12 – 12/12 | 0.0236” | 2′ 6″ – 45′ | 10″ – 28″ |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For NS25 or NS38 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 48”

Standard Panel Widths

| GAUGE | NS25 | NS38 |

|---|---|---|

| 24 | 19.56″ | 18.56″ |

Oil Canning

- Oil Canning is a naturally occurring phenomenon inherent in all sheet metal

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Fasteners at maximum 2′ centres

- Snap-in-place design

Side Lap Detail

Overlap Construction

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Continuous nail strip

- Knee Caps available

- No seamer required

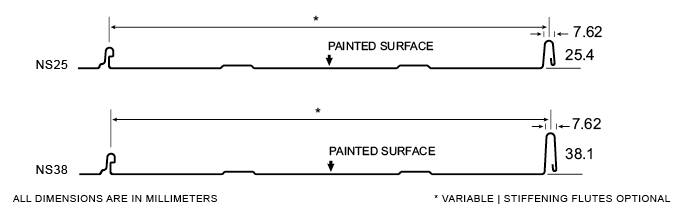

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| NS 25 | 3/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

| NS38 | 1.5/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For NS25 or NS38 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 1,219 mm

Standard Panel Widths

| GAUGE | NS25 | NS38 |

|---|---|---|

| 24 | 497 mm | 471 mm |

Oil Canning

- Oil Canning is a naturally occurring phenomenon inherent in all sheet metal

- Oil Canning is not a valid reason for rejection of these products

Installation

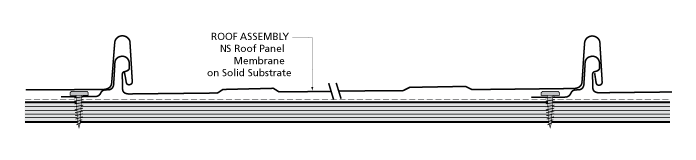

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Fasteners at maximum 2′ centres

- Snap-in-place design

Side Lap Detail

Overlap Construction